Metal cutting technology is imperative in today’s era, as it requires ardent precision, and skilled craftsmanship. With time, metal cutting technologies has evolved, and today there are plethora of advanced metal cutting tools. What are they? Do you want to know about them? Read this post. Here we will focus on four important types of metal cutting tools used in industrial metalworking projects.

4 Types of Metalworking Tools in Industrial Metal Working Projects

There are various tools used in industrial metalworking projects.These tools are capable of cutting various types of steels, as well as other metals. Below are their applications.

- Band Saws: Band saws are made from continuous piece of metal, which rotates on minimum of two wheels. The teeth on the edge enables the saws to cut metals and other hard materials.

-

-

- The saws are used for cutting serrated or irregular metals with the help of high precision blades.

- It can produce smoothest cuts at 45 and 90 degree angles.

Browse Best Quality Woodward Fab Band Saw Product Range:

PRODUCT SKU/TYPE Miter Cutting Band Saw WFS712 Manual Miter Band Saw WFS56 -

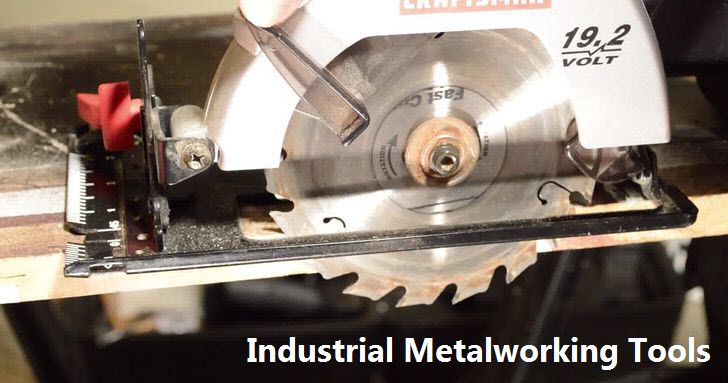

- Evolution Metal Cutting Circular Saws: Evolution metal cutting tool incorporates more revolutionary technology with its high blade power, bevel cutting, and extra laser guide feature.

- These saws are designed to cut hard metals such as steel, aluminum, cast iron pipes, and stainless steel. The saws produce instantly workable surfaces with no traces of heating or burring.

- These saws are robust and highly durable. Also, there is a clear visibility panel to aid in accurate cutting of metal parts.

Browse Best Quality Evolution Metal Cutting Circular Saws Product Range:

| PRODUCT | SKU/TYPE |

| Evolution Metal Cutting Circular Saws SAW-C7 Steel | SAW-C7 Steel |

| Evolution Metal Cutting Circular Saws Stainless | SAW-C7 Stainless |

| Evolution Metal Cutting Circular Saws Aluminum | SAW-C7 Aluminum |

| Evolution Metal Cutting Circular Saws Steel | SAW-C7.25 |

| Evolution Metal Cutting Circular Saws Fury | SAW-C7.25 Fury |

| Evolution Metal Cutting Circular Saws SAW-C9 Steel | SAW-C9 Steel |

| Evolution Metal Cutting Circular Saws SAW-C9 Stainless | SAW-C9 Stainless |

| Evolution Metal Cutting Saws Aluminum SAW-C9 Aluminum | SAW-C9 Aluminum |

- Chop Saw: Chop saws are basically deployed for those metal fabrication process, where lot of bevel or angled cutting is involved.

-

-

-

- Fast swivel action, and hi-torque gearbox reduces motor load, and improves performance.

- The saws are ideal for cutting square tube, angle iron, steel plate, pipe, tube, and metal roofing.

Browse Best Quality Chop Saws Product Range:

PRODUCT SKU/TYPE Chop Saw Steel Cutting Blade SAW-C14 Steel Aluminum Cutting Blade Chop Saw SAW-C14 Alum Stainless Steel Cutting Blade Chop Saw SAW-C14 Stain Steel Cutting Blade Chop Saw SAW- C15 Steel -

-

-

- Cold Saws: These saws are equipped with circular blades, and are used for mainly cutting ferrous and non-ferrous materials.

- The saw features a heavy duty blade, which can be set to an adjustable depth to produce a desired cut, and a laser guide to help in the accurate cutting of the metals, bars and etc.

- Also, this saw is equipped with a coolant system, which helps keep the saw blade teeth cooler, and lubricated.

Browse Best Quality Cold Saws Product Range:

| PRODUCT | SKU/TYPE |

| Cold Saw WFCS350 14″ Blade | WFCS350 |

| Cold Saw WFCS315 12″ Blade | WFCS315 |

| Cold Saw WFCS250 10″ Blade | WFCS250 |

For the cutting process, the several subsets of tools can help the metalworker and industries decide the best cutting option for the given metal. If puzzled about the right type of cutting tool for your next industrial metalworking project, you should immediately consult an expert or a manufacturer like Woodward Fab. The company provides quality metal cutting inventory at most competitive prices. To know more about our products or placing an order online, please click here.

Related Post:

- Tool Mastery: How Expertise with Your Equipment Impacts Sheet Metal Results

- How the Electric Vehicle market is driving changes in sheet metal fabrication technology

- Sheet Metal Bend Relief Guidelines: Ensuring Successful Fabrication

- Cold Rolled Steel Sheets vs. Hot Rolled Steel Sheets: Which is Right for Your Project?

- Essential Tools and Equipment for Ductwork Fabrication: Ensuring Efficiency and Quality