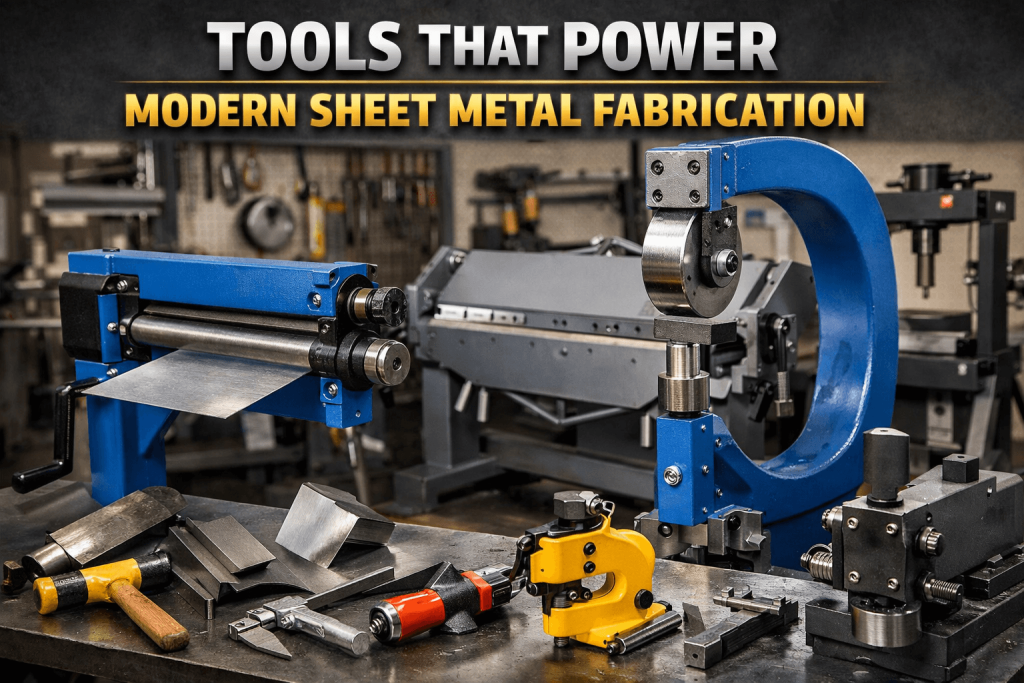

Sheet metal fabrication is a craft that blends precision, strength, and creativity. Whether it’s automotive restoration, HVAC work, custom metal art, or industrial manufacturing, the quality of tools used plays a critical role in the final result. This is where Woodward Fab has built a strong reputation by providing reliable, durable, and performance-focused sheet metal fabrication tools for professionals and hobbyists alike.

For decades, Woodward Fab has been known as a trusted name in the metalworking industry, offering equipment designed to make cutting, shaping, bending, and forming metal more efficient and accurate.

What Is Woodward Fab Known For?

Woodward Fab specializes in sheet metal fabrication equipment and workshop tools that support a wide range of fabrication tasks. Their products are commonly used in:

- Automotive body repair and restoration

- Custom vehicle building

- HVAC fabrication

- Small fabrication shops

- DIY and hobby metalworking

- Industrial metal forming projects

The brand focuses on delivering tools that balance affordability, durability, and professional-grade performance, making them suitable for both beginners and experienced fabricators.

Core Categories of Woodward Fab Tools:

Woodward Fab’s product range covers nearly every essential process in sheet metal work. Below are the major categories of tools they provide:

1. Metal Forming & Shaping Tools

These tools are designed to help fabricators create curves, contours, and structural reinforcements in sheet metal.

English Wheels

Used for forming smooth compound curves in metal sheets. They are especially popular in automotive body panel fabrication where precision curves are required.

Bead Rollers

Bead rollers add strength and decorative patterns to sheet metal panels. They are widely used for reinforcing large flat panels and enhancing visual design.

Shrinkers and Stretchers

These tools allow metal to be compressed or expanded at specific points, enabling the creation of complex shapes and tight curves.

2. Cutting & Punching Tools:

Accurate cutting is the foundation of good fabrication work. Woodward Fab provides multiple options for clean and efficient cutting.

Hand Shears & Throatless Shears

Ideal for straight or curved cuts without distorting the metal. Throatless shears allow greater flexibility when cutting intricate shapes.

Nibblers and Punch Tools

Useful for detailed and internal cuts, nibblers are perfect for creating complex outlines without warping the surrounding metal.

Hole Cutters & Step Drills

Designed for precise, burr-free holes in thin and thick metal sheets alike.

3. Bending & Bracket Making Tools:

Bending tools help create angles, folds, and brackets essential for structural components.

Bracket Maker Benders

These compact tools allow accurate bends for brackets and mounting plates, commonly used in mechanical assemblies.

Tube and Pipe Benders

Essential for shaping round metal stock used in roll cages, frames, exhaust systems, and structural supports.

4. Multi-Function Press & Forming Machines:

For workshops that need versatility, Woodward Fab offers machines capable of handling multiple fabrication tasks.

Multi Press Machines

These presses use interchangeable dies to perform bending, punching, notching, and forming operations. They are valuable space-saving solutions for small and mid-sized shops.

Corner Notchers & Forming Dies

Attachments and dies expand machine capabilities, allowing precise cuts and shapes for professional-quality results.

5. Power Tools & Workshop Equipment:

Beyond shaping and cutting, Woodward Fab also supports general workshop needs with power tools and heavy-duty equipment.

- Hydraulic presses

- Band saws

- Welding positioners

- Air tools and sanders

- Grinding and finishing accessories

These tools enhance workflow efficiency and ensure smoother finishing and assembly processes.

Why Do Fabricators Choose Woodward Fab?

Several factors contribute to the brand’s popularity among metalworkers:

Durability – Tools are built with strong materials designed for repeated use.

Precision – Equipment is engineered for accuracy, reducing rework and material waste.

Accessibility – Products are suitable for both beginners and professionals.

Versatility – A wide product line allows workshops to scale and diversify their capabilities.

Value for Money – Offers professional features without extreme pricing.

Ideal Users of Woodward Fab Tools

Woodward Fab equipment is commonly chosen by:

- Automotive restoration specialists

- Custom bike and car builders

- HVAC technicians

- Small fabrication shop owners

- Educational workshops and training centers

- DIY hobbyists entering metalworking

This broad usability is one of the brand’s biggest strengths tools are not limited to a single industry or skill level.

Final Thoughts:

Sheet metal fabrication demands tools that deliver precision, strength, and consistency. Woodward Fab has positioned itself as a reliable partner for fabricators by offering a comprehensive lineup of machines and accessories that cover nearly every stage of the metalworking process.

From shaping smooth automotive curves with an English wheel to reinforcing panels with a bead roller or executing precise bends with bracket makers and presses, Woodward Fab tools empower users to transform raw metal into high-quality finished products. For workshops looking to improve efficiency and craftsmanship, investing in dependable fabrication tools can make all the difference and Woodward Fab continues to be a name many fabricators trust.

Related Post: