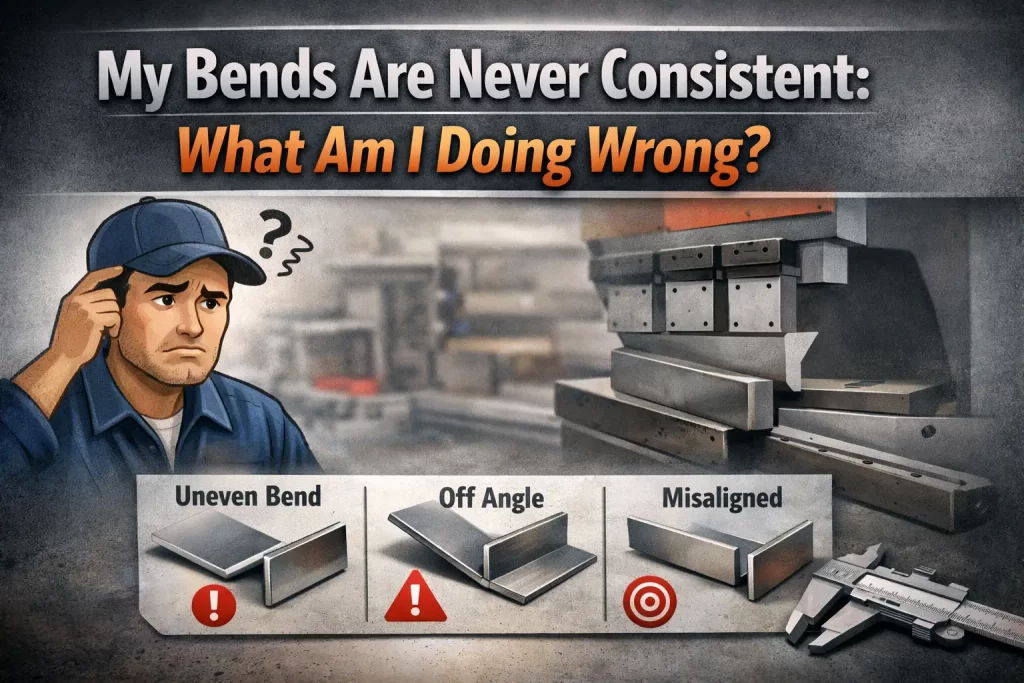

In sheet metal fabrication, consistency is everything. One clean, accurate bend can make a project look professional but inconsistent bends can quickly ruin alignment, weaken structure, and waste expensive material. If you often find that your bends are slightly off, uneven, or unpredictable, you’re not alone. This is one of the most common challenges faced by both beginners and experienced fabricators.

The good news? Inconsistent bending is usually caused by a handful of fixable issues. Once you understand the root causes, you can dramatically improve accuracy and confidence in your work.

Why Consistent Bending Matters?

Poor bending accuracy can lead to:

- Misaligned assemblies

- Weak joints and poor structural strength

- Increased rework and material waste

- Customer dissatisfaction in professional jobs

- Loss of time and profitability

Consistency is not just about looks it affects durability, safety, and overall project success.

Common Reasons Your Bends Are Inconsistent

1. Incorrect Tool Selection

Not all bending tools are designed for every type or thickness of metal. Using a light-duty bender for thick steel, or a heavy industrial brake for thin aluminum, can lead to unpredictable results.

Solution:

Choose tools based on:

- Material type (steel, aluminum, stainless)

- Thickness (gauge)

- Bend angle requirements

- Project scale

Reliable, purpose-built bending equipment like the Woodward Fab sheet metal brakes and benders is designed with adjustable settings and strong construction that helps maintain repeatable accuracy across different materials.

2. Inconsistent Material Thickness

Even small variations in sheet thickness can change how metal reacts to pressure. Lower-quality sheets often have uneven gauge distribution.

Solution:

- Buy metal from reputable suppliers

- Measure thickness before bending

- Group similar sheets together for batch jobs

3. Lack of Proper Measurement and Marking

Eyeballing measurements almost always leads to errors. Even a few millimeters off can throw off an entire project.

Solution:

- Use steel rulers, digital calipers, and angle gauges

- Mark bend lines clearly with a scribe instead of a marker

- Double-check measurements before each bend

4. Improper Machine Calibration

Machines gradually lose alignment from vibration and repeated use. A brake or bender that is even slightly out of square will produce uneven bends.

Solution:

- Perform regular calibration checks

- Ensure clamping bars and dies are straight

- Tighten bolts and fasteners weekly

Many professional fabricators prefer Woodward Fab bending machines because they are built with rigid frames and precise adjustment mechanisms, making calibration easier and more stable over time.

5. Uneven Pressure Application

Manual bending especially can suffer from inconsistent force. Applying more pressure on one side results in twisted or angled bends.

Solution:

- Apply force evenly across the handle or lever

- Use two-hand operation when possible

- Consider foot-operated or power-assisted benders for larger jobs

Foot-operated bead rollers and benders from Woodward Fab are popular for this reason they allow better control and balanced pressure, improving uniformity.

6. Ignoring Springback

Metal naturally tries to return to its original shape after bending. Different metals have different “springback” behavior.

Solution:

- Slightly over-bend to compensate

- Practice on scrap material first

- Learn the springback characteristics of each metal type

7. Worn Dies or Blades

Over time, tooling surfaces wear down, causing uneven pressure and inaccurate angles.

Solution:

- Inspect dies regularly

- Replace worn tooling promptly

- Use hardened, high-quality dies

Woodward Fab offers replaceable die sets and accessories, which help maintain precision without replacing the entire machine.

Best Practices for Perfect Bends Every Time:

Create a Test Piece First

Always test bends on scrap metal before working on your final material. This saves cost and allows fine-tuning.

Use Consistent Workflow

Follow the same order of operations every time. Consistency in process leads to consistency in results.

Maintain Your Equipment

Clean machines after use, lubricate moving parts, and keep adjustment screws tight.

Invest in Quality Tools

While technique matters, high-quality tools dramatically reduce margin of error. Equipment built with strong frames, accurate scales, and smooth mechanisms provides a solid foundation for precision work.

How the Right Equipment Makes a Difference?

Fabricators who upgrade from generic or low-cost bending tools often notice immediate improvement in consistency. Woodward Fab sheet metal brakes, bracket benders, and multi-purpose presses are designed with:

- Heavy-duty steel construction

- Adjustable clamping systems

- Precision angle guides

- Replaceable tooling

- Smooth lever and foot controls

These features allow both beginners and professionals to achieve repeatable, professional-grade bends without excessive trial and error.

Final Thoughts:

If your bends are never consistent, the issue is rarely just “skill.” More often, it’s a combination of measurement habits, material quality, tool condition, and equipment capability. By improving your process and using dependable fabrication tools, you can turn bending from a frustrating task into a predictable and satisfying one.

Consistency comes from the right mix of practice, precision, and proper equipment and when those three align, your sheet metal projects will not only look better but perform better too.

Related Post: