In the metalworking industry, metal bending and shaping are performed using specialized equipment called press brakes. Although designed for precision bending, the problem with this equipment is that it needs highly experienced operators with 100% working focus. However, no matter how experienced and vigilant the operator is, he is always at the risk of injury while handling the press brake. Therefore, press brake safeguarding to prevent injuries is a necessity. The Occupational Safety and Health Administration (OSHA) and other organizations have set standards to assure the safety of people working with it. This post focusses on the industrial safety standards and press brake safety guidelines to be followed.

Industrial Safety Standards to Avoid Common Press Brake Hazards

In order to avoid accidents with press brake, metalworking service providers need to comply with the following standards.

- OSHA- General Duty Clause 1910.212: This standard is set by the Occupational Safety and Health Administration (OSHA) for industrial safety. It requires business owners to provide industrial protection to employees.

- ANSI B11.3: The American National Standard Institute (ANSI) has set the safety standard for operating heavy-duty, hazardous industrial equipment. The use of press brakes is cited under this standard, therefore many industries in the United States follow ANSI B11.3- 2012. This ANSI standard advises the use of Active Opto-electronic Protective Devices (AOPD) to avoid common press brake hazards. It also sets a speed limit of restrictive10 mm/sec for press brake operation.

Now as the safety standards are discussed, the question arises, how to safeguard press brakes?

Let us discuss some ways to safeguard press brakes to avoid accidents at the workplace.

How to Safeguard a Press Brake?

Different ways to secure the press brake system and operators from accidental hazards are detailed as follows.

- Awareness Barrier: Awareness barrier is one of the effective ways of safeguarding press brakes. It involves securing the back end of the press brake machine from any interruption. Depending on local OSHA standards, it is important to protect backend by adding an awareness cable, chain, or barrier with a pictorial warning sign. This isn’t considered a preventive measure but a caution indication.

- Barrier Guards: According to OSHA standards, the press brakes are to be protected with barrier guards, on both the ends. The interlocked barrier guards can be used to prevent hands from going inside the machine area while the operator tries to reach the punch and die. The latest barrier guards feature electrically interlocked fasteners that prevent any manual flawed activity during the operation.

- Light Curtains: Light curtains are sensitive surfaces between the operator and press brake. These safeguarding tools feature vertically positioned transmitters and receivers where laser beams transmit in between. These laser beams create a vertical sensing surface between the operator and the machine. If anytime the operator’s hand comes in contact with the laser curtain, the machine will stop working. It is only possible in press brakes due to the quick responsive nature of the machine. These machines are hydraulic, therefore act immediately on the termination or activation commands. This is a truly effective safeguarding tool used to avoid accidents with a press brake. However, it is very important to function-test the light curtains to the machine model-specific standards.

- Two-Hand Controls: This is another effective method of protecting hand injuries caused by press brakes. These devices inspire operators to use both their hands to trigger the stroke. There are two buttons on each side of the device, which must be pressed at the same time to start the press brake. If a button is not pressed properly then the machine will stop working.

- Laser AOPD: Laser AOPDs is the latest press brake safeguarding technology. This technology offers to safeguard to absolute zero distance. It features speed limit monitoring as well as operator safety. If these AOPD tools are installed and operated correctly, it can give absolutely safety from press brake accidents.

FAQ (Frequently Ask Questions)

Why is it important to safeguard a press brake?

Safeguarding a press brake is crucial to protect operators and other personnel from potential hazards and injuries that can occur during its operation. By implementing proper safeguards, you can minimize the risk of accidents and ensure a safe working environment.

What are the common hazards associated with press brakes?

Common hazards associated with press brakes include the risk of being caught in the moving parts, crushed by the machine, struck by ejected materials, or exposed to high levels of noise, vibrations, or hazardous substances. Inadequate safeguarding can lead to serious injuries or fatalities.

What are the legal requirements for safeguarding press brakes?

Legal requirements for safeguarding press brakes may vary depending on the jurisdiction and industry. However, most countries have regulations and standards, such as the Occupational Safety and Health Administration (OSHA) in the United States, that outline specific requirements for safeguarding machinery, including press brakes.

What are the key components of press brake safeguarding?

The key components of press brake safeguarding include physical barriers, such as fixed or movable guards, light curtains, and interlocks. Control systems like two-hand controls and presence-sensing devices are also important. Proper warning signs and labels should be displayed, and emergency stop buttons should be easily accessible.

Are there any specific safety considerations for press brake tooling?

Yes, press brake tooling should be properly installed, maintained, and inspected regularly to ensure its safety and effectiveness. The tooling should be appropriate for the material being bent and secured tightly to prevent any movement during operation. Operators should also be trained in proper handling and storage of tooling.

How often should press brakes be inspected for safety?

Press brakes should be inspected regularly, following the manufacturer’s guidelines and any relevant safety regulations. The frequency of inspections may vary depending on factors such as the intensity of machine use and the specific requirements of the industry. Regular maintenance and inspection schedules should be established and adhered to.

What are some signs that indicate a press brake safeguarding system needs maintenance or repair?

Signs that indicate a press brake safeguarding system may need maintenance or repair include damaged or missing guards, malfunctioning interlocks or sensors, inconsistent or unexpected machine behavior, unusual noises or vibrations, or any other deviation from normal operating conditions. If any safety concerns are identified, the machine should be immediately taken out of service until the issue is resolved.

What should I do if I encounter a safety issue or hazard while using a press brake?

If you encounter a safety issue or hazard while using a press brake, you should immediately stop the machine and follow established emergency procedures. Report the issue to your supervisor or the appropriate personnel responsible for safety in your workplace. It is important to address safety concerns promptly to prevent accidents and ensure the well-being of everyone involved.

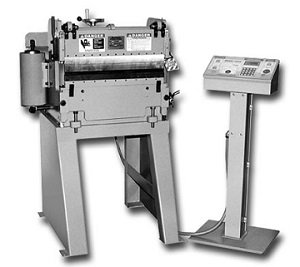

Now that the safety standards and safety tools are discussed, it is important to know the quality of equipment is the biggest safety measure. If you buy poor quality press brakes, then all these safeguarding tools and techniques together may not work for you. Therefore, you must buy bench top budget brake machines from a prominent supplier like Woodward-Fab. The company is involved in sheet metal bending tools and equipment manufacturing and supply since 1966. Their experience assures quality and customer satisfaction.

Related Post:

- Tool Mastery: How Expertise with Your Equipment Impacts Sheet Metal Results

- Reducing Waste, Maximizing Efficiency: Strategies to Minimize Material Loss in Sheet Metal Bending

- Sheet Metal Bending in Architectural Design: Transforming Buildings with Curved Metal

- How to Optimize Your Metal Fabrication Workflow

- Why Every Automotive Fabricator Needs an English Wheel: Benefits, Tips, and Safety Precautions