As the bending techniques differ, it is hard to provide a definite list of safety measures. This post provides a generic list of the safety measures to be taken while using hydraulic pipe benders.

Understanding Hydraulic Pipe Benders

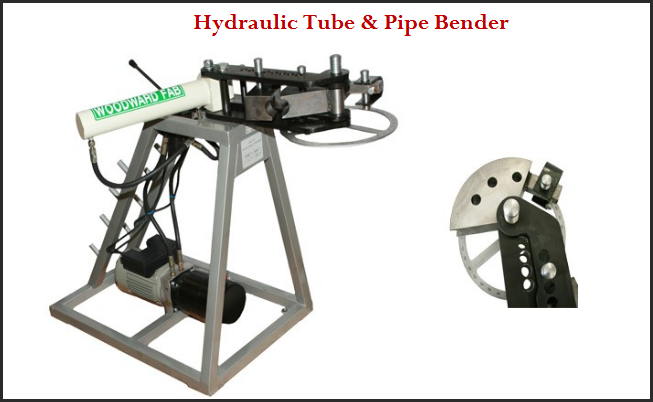

Hydraulic pipe benders are powerful tools used to bend pipes and tubes with precision and ease. It utilize hydraulic pressure to apply force on the pipe, allowing it to be bent to the desired angle or shape. Let’s explore the basic principles of how hydraulic pipe benders work, the different types available, and their applications in various industries.

How Hydraulic Pipe Benders Work?

- Hydraulic System: Hydraulic pipe benders consist of a hydraulic pump, cylinders, and control valves. The hydraulic pump generates pressure by forcing hydraulic fluid into the cylinder.

- Cylinder and Ram: The cylinder houses a ram, which is a movable piston-like component. The ram exerts force on the pipe to bend it. The cylinder is designed to handle the required pressure and has a set of seals to prevent fluid leakage.

- Bending Dies: Bending dies are essential components that determine the angle and radius of the bend. They are positioned in the desired configuration to guide the pipe during the bending process.

- Control Mechanism: Hydraulic pipe benders have control valves to regulate the flow of hydraulic fluid. These valves allow operators to control the bending speed and pressure applied to the pipe, ensuring precise and accurate bends.

- Hydraulic Pressure: When hydraulic fluid is pumped into the cylinder, it pushes the ram forward, exerting force on the pipe. The force applied causes the pipe to deform and bend around the bending dies. The pressure can be adjusted based on the material and diameter of the pipe being bent.

Steps to Using a Hydraulic Pipe Bender

Now that we have a basic understanding of the hydraulic pipe bender’s components, let’s dive into the step-by-step process of using it effectively.

Step 1: Safety First

Always start by putting safety first. Ensure you wear appropriate safety gear, including gloves and safety glasses, to protect yourself during the bending process. Safety should never be compromised.

Step 2: Pipe Preparation

Prepare the pipe by measuring and marking the point where you want the bend to occur. Use a chalk or marker to make clear and precise marks, ensuring accuracy in your project.

Step 3: Setting Up the Bender

Position the hydraulic pipe bender on a stable surface or workbench. Ensure it is securely anchored to prevent any movement during operation. Check that the cylinder and pump are properly connected and in good condition.

Step 4: Pipe Insertion

Carefully insert the pipe into the bender, aligning it with the cylinder and ensuring it’s snugly in place. Double-check that the marks you made align with the bending point indicators on the bender.

Step 5: Hydraulic Pressure Adjustment

Start the hydraulic pump and gradually apply pressure to the pipe. It’s crucial to apply pressure slowly and consistently to avoid over bending or damaging the pipe. Refer to the bender’s manual for recommended pressure settings.

Step 6: Bending

As you apply pressure, you will notice the pipe gradually bending. Keep a close eye on the alignment and angle to ensure it meets your project’s specifications. If adjustments are needed, release pressure and make them before continuing.

Step 7: Finalizing the Bend

Once you achieve the desired bend angle, release the hydraulic pressure and carefully remove the bent pipe from the bender. Inspect the bend for any defects or irregularities, and make adjustments if necessary.

Step 8: Safety Shutdown

After completing your bending task, turn off the hydraulic pump and release any remaining pressure. Safely store the hydraulic pipe bender and clean up your workspace.

Different Types of Hydraulic Pipe Benders:

- Manual Hydraulic Pipe Benders: These benders require manual operation & are commonly used for lighter-duty applications. They are portable and suitable for on-site bending tasks.

- Electric Hydraulic Pipe Benders: Electrically powered pipe benders are more robust and offer higher bending capacities. They are typically used in workshops or industrial settings where power outlets are available.

- Hydraulic-Powered Pipe Benders: These benders are driven by a dedicated hydraulic power unit. They offer the highest bending capacity and are ideal for heavy-duty industrial applications.

Applications of Hydraulic Pipe Benders:

- Construction Industry: Hydraulic pipe benders find extensive use in the construction industry for bending pipes used in plumbing, heating, ventilation, and air conditioning (HVAC) systems. They are also employed in the fabrication of structures such as handrails, fences, and gates.

- Manufacturing and Fabrication: Industries involved in manufacturing and fabrication of metal structures utilize hydraulic pipe benders to create bent pipes and tubes for various applications, including automotive components, furniture, and machinery.

- Oil and Gas Industry: Hydraulic pipe benders are employed in the oil and gas industry for bending pipes used in pipelines, refineries, and drilling rigs. They allow for the precise bending of pipes to accommodate complex layouts and optimize fluid flow.

- Aerospace Industry: Hydraulic pipe benders are utilized in the aerospace industry for manufacturing aircraft components and systems. They enable the creation of bent pipes used in fuel systems, hydraulic systems, and air conditioning systems.

- Agricultural Sector: Hydraulic pipe benders play a role in the agricultural sector by bending pipes used in irrigation systems, farm machinery, and equipment. They help create custom configurations to suit specific requirements.

Safety Measures While Using Hydraulic Pipe Benders:

The following are some of the important safety measures that should be followed while using hydraulic pipe bending equipment:

- Check the pipe bender thoroughly. Check for any damage or defect. Make sure to do this check every time while using the pipe.

- Make sure that the roller shafts are properly pinned, prior to using the pipe. Also, ensure that the bending die is properly seated, so that there is no mishap.

- The pipe should be cleaned regularly, so that its performance is not lowered.

- Always remember to keep your hands away from the die and rollers while you are bending the pipe.

- It is always recommended to consult a professional when it comes to maintaining and lubricating the hydraulic unit.

- Always use the right hydraulic oil during the maintenance.

- You should only use hydraulic oil. Avoid using brake fluid.

- If you find the pipe bender in a damaged state, you should not use it.

- You should never exceed the rated capacity of the hydraulic units.

- Use the hydraulic pipe bender only for the purpose it is meant for, and not for any other purpose.

- You should not change the valve settings of pressure control.

- Always make sure that you store the hydraulic pipe in a cool and dry place when it is not in use. This prevents moisture and formation of moss on the pipe.

- Read and understand the instruction manual before using the pipe bender.

- In order to ensure performance, make sure that all the shafts are fitted correctly and the pip rollers are in the right holes.

- For achieving the right degree of bend, you should ensure that the pump and valve handle are in the correct position

- It is always recommended to replace the hydraulic oil every year.

- While using the high pressure hose, you should make sure that both the ends are clean otherwise the pipe bender will not operate properly.

- Do not take off the nameplates and labels because they include important safety instructions.

The hydraulic pipes come in different shapes and sizes. Thus, it is required to take the actual equipment into account while following the aforementioned safety measures.

Browse Best Quality Pipe and Tube Benders Product Range:

| PRODUCT | SKU/TYPE |

| Hydraulic Pipe and Tubing Bender | WFPB1000 |

| Manual Tube & Pipe Bender | WFB2 |

Related Hydraulic Pipe Benders Blog Posts:

- Top Pipe Benders Offered by Woodward Fab

- How to Use a Pipe Bender Effectively? – Part I

- How to Use a Pipe Bender Effectively? – Part II

- How to Find Right Tube Bender for Your Needs?

- Hydraulic or Manual Pipe and Tube Bender – What is Your Choice?

- 7 Simple Tips to Improve Bending Processes with a Pipe Bender

- 5 Tips for Perfect Pipe Bending Using a Pipe Bender

- Common Mistakes to Avoid While Buying Tube Bending Machine

- Step-by-step Guide to Assembling the Manual Pipe & Tube Bending Machine